Business

Stamped: Overview – Stamped Products, Benefits, Features Of Stamped And Its Experts Of Stamped.

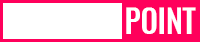

Stamped is a platform that provides customer reviews and ratings solutions for businesses of various sizes.

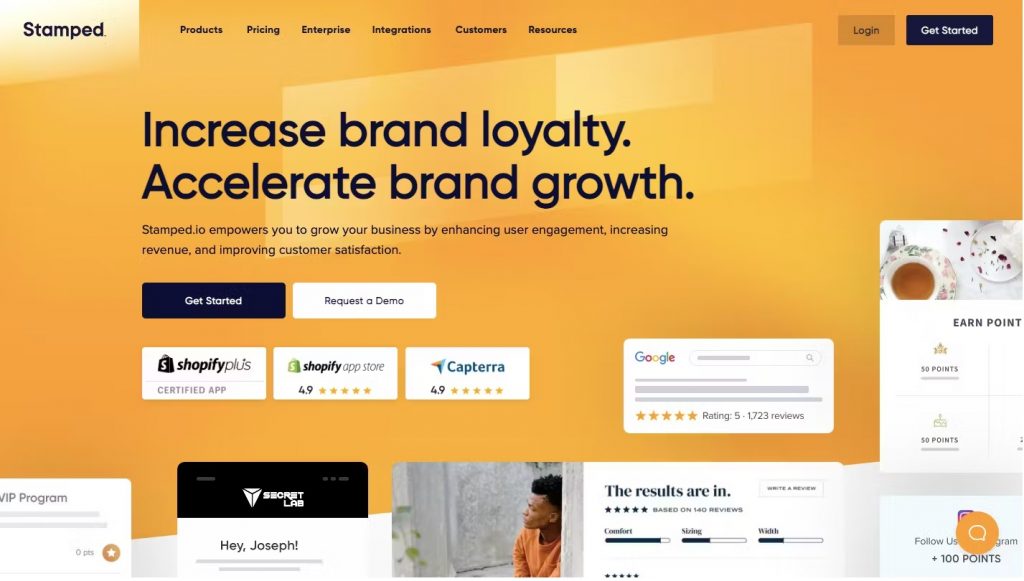

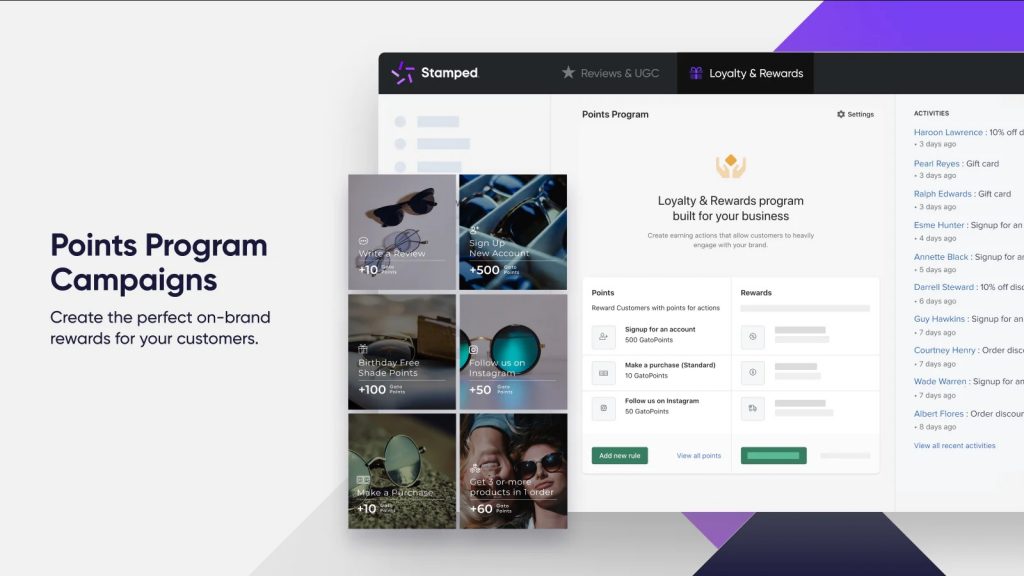

Stamped is a platform that provides customer reviews and ratings solutions for businesses of various sizes. The platform allows businesses to collect and display customer feedback, as well as showcase their products and services in a more engaging way. Stamped offers features such as automated review requests, customizable review forms, product upselling and cross-selling, and integration with popular e-commerce platforms like Shopify, Magento, and Woo Commerce. The platform also provides advanced analytics and reporting tools, allowing businesses to gain insights into customer behavior and preferences. Stamped helps businesses build social proof and trust, increase sales and customer loyalty, and improve their online reputation.

Stamped Overview

Stamped has had a tremendous impact on my life. Stamped is a mobile application that allows users to discover and share recommendations for restaurants, bars, and other local businesses. Users can search for businesses based on their location, read reviews from other users, and share their own experiences and recommendations. Stamped also offers personalized recommendations based on the user’s previous reviews and preferences. The app also allows users to earn rewards and discounts for their reviews, and to connect with friends and influencers to see their recommendations. Stamped was founded in 2011 and was acquired by Yahoo! in 2012.

Stamped Products

Stamped products refer to a type of manufacturing process used to create a wide range of metal products. The process involves using a press machine to shape or cut metal sheets into the desired shape and size. In the stamping process a metal sheet is placed between two dies, and pressure is applied to the top die, forcing the metal sheet to conform to the shape of the bottom die. This process can be used to create a variety of shapes, including flat pieces, rounded shapes, and complex 3D designs. Stamping is commonly used in the production of automotive parts, household appliances, electronic components, and many other products that require precise and durable metal parts. The process is highly efficient and can be automated, making it an ideal choice for large-scale manufacturing. Stamped products offer many advantages over other manufacturing techniques, including high accuracy, consistent quality and the ability to create complex shapes with a single operation. Stamped products can be produced at a lower cost than many other types of metal parts, making them a cost-effective choice for many industries

Benefits And Features Of Stamped

Benefits

- High Precision: Stamping Allows for high precision and accuracy in the manufacturing of metal parts. This means that Stamped products can be made to exact specifications and tolerances, ensuring that they perform as intended.

- Cost-Effective: Stamping is an efficient and cost-effective manufacturing process, particularly for high-volume production runs. It is also a versatile process that can be used to produce a wide range of products.

- Durability: Stamped products are often made from high-strength materials, making them durable and long-lasting. This makes them ideal for applications that require parts to withstand high levels of stress or wear and tear.

- Consistency: Stamping is a highly repeatable process, which means that products can be produced with consistent quality and performance. This is important for ensuring that products meet customer specifications and expectations.

Features

- Material Flexibility: Stamping can be used to process a wide variety of metals, including aluminum, brass, copper, stainless steel, and more. This allows for flexibility in the choice of materials for a given application.

- Complex Geometry: Stamping can create complex geometries in sheet metal, including curves, bends, and tapered shapes. This allows for a wide range of part shapes and sizes.

- Tight Tolerances: Stamping can achieve tight tolerances in the production of parts, which ensures accuracy and consistency in part dimensions.

- High Production Rates: Stamping can be automated for high-volume production runs, which allows for quick and efficient manufacturing of large quantities of parts.

- Customizable Tooling: The tooling used in stamping can be customized to meet specific production requirements, including part geometry and tolerances.

Experts Of Stamped

- Stamped is fast and convenient, allowing users to quickly send and receive money.

- It is a secure platform that protects user data and payment information.

- It offers a variety of features such as automated payments and recurring payments for added convenience.

- Fees are low compared to other services, making it an affordable option.

- Stamped has excellent customer service, providing users with timely responses to inquiries and issues.

Stamped Conclusion

Stamped is a powerful tool for businesses and organizations alike. It helps them to build relationships with customers in an efficient and organized manner, while also providing useful insights on customer behavior. The software offers a variety of features that make it easy to customize how data is collected and organized. Stamped is a valuable asset for businesses wishing to gain a better understanding of their customer base. Stamped is a powerful tool for creating and sharing knowledge. It helps bring together information in a way that allows users to quickly and effectively access relevant data. The platform has a lot of potential to be used as an educational resource and it is likely that more people will use it as a way to create meaningful connections between different topics. Stamped makes it easy to quickly collect organize and share information with others making it a valuable platform for both casual and serious learners alike.